- History

- Technical Questions

- To know a Laguiole

- Laguiole upper parts details

- The bladestop

- From steel bar to knife

- Closing systems for pocket knives

- How to sharpen your knife ?

- Sharpening stones

- Unkeep of folding knives

- Upkeep of your kitchen knife

- Cutlers adresses

- Stainless steel and carbon knife

- The art of shaving with the straight razor

- Upkeep of straight razor

- Materials

Closing systems for pocket knives

Keeping a knife handy is always a good thing, having a folding one makes it so much easier to carry around! Over many years, the Laguiole folding knife has become a household name in terms of pocket knives.

While the size of the knife may slightly differ from one design to the other, locking systems vary completely.

Front or back pump – liner-lock, lockback or locking collars, there are many ways to lock a folding knife. In this Club Laguiole article, learn about the subtleties of each Laguiole knife locking system, spot the advantages and uses of each system and make an enlightened choice.

You too, become a connoisseur of Laguiole knives, discover the characteristics of each mechanism and which one is best suited to how you use your knife. More than a general knowledge article, this is the information you need to choose your next Laguiole purchase.

Cutlery makers work on improving existing locking systems. They also design original systems which they jealously patent.

What is a knife spring for ?

A spring is an organ or mechanical part which uses the elastic properties of certain materials to store mechanical energy, produce movement.

In cutlery making, the spring’s purpose is to facilitate the safe opening and locking of the blade while ensuring support, whatever its position.

Not all folding knives possess a spring to support the blade. The Capucin, a simple design, only has two nails. For all other folding knives, it would be more accurate to talk about ‘springs’ in the plural form, since their shapes can vary as much as locking systems.

Locking systems are also designed to ensure user safety when the knife is in open position, their aim is to guarantee optimal use of the knife, in total safety.

Locking systems can be divided into 6 broad families

The closing systems can be classed in 6 different categories:

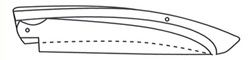

- the slipjoint

It is the traditional system for Laguiole folding knives. Here are a few examples of knives with a slipjoint locking system.

The most common of springs system is the slipjoint : the spring is lodged in the upper part of the handle between two plates and pushes against the tang of the blade to keep it open or folded.

Here are a few examples of knives with flat spring blade closure, also known as ‘forced notch’.

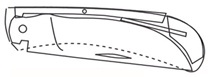

- Pump Locks

Find out all about our knives fitted with pump locking systems.

The pump locking system is an improvement on the lockback. It appeared towards the end of the 19th century thanks to adjusting techniques brought by the industrial revolution. The pump mechanism allows for the same effects as the lockback but without needing the cumbersome locking ring. The lockback hook is still present, but it is now a part of the mechanism which is part of the handle’s back.

To unlock the knife, no need to apply force to fold the knife. A slight pressure with the left hand and follow the blade with your right hand (for right-handed users). As soon as pressure is released, the pivot goes back to its initial position.

- Back pump

- Front pump

Discover our range of knives with pump closure or also know lock security pressure. There is no need to force the blade to close, all you need do is lightly squeeze it shut with the left hand, while guiding the blade with the right (if you are right-handed).

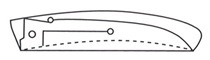

- Liner lock

You’ll also find a selection of knives with a liner-lock system. On such a knife, one of the plates is cut out and acts as a spring. It folds inside when the knife is open, and presses on the flat end of the tang. To unlock , simply disengage by pressing the liner with your thumb.

You will also find a selection of knife models with locking plate closure, also known as ‘liner-lock’.

- Locking collar

This is a very common mechanism on traditional knives such as Opinels.

A steel colla ris fitted by the manufacturer between the blade and the handle : to lock the blade in place, just manually rotate the collar To unlock it, rotate the collar again until the blade is freed.

At Actiforge we fit our regional Nontron knives with a locking collar system. Collar folding knives can stand intensive use or being used in extreme conditions (humidity, temperature changes, muddy or alkaline environments…) Thus, this rather rudimentary locking system was designed with tough conditions in mind.

On these locking mechanisms, several joining systems can be found between the spring and the blade.